High Temperature Resistant Fabric Expansion Joints are critical components in modern industrial systems, designed to accommodate the dynamic movements and thermal fluctuations encountered in piping and ductwork. These highly flexible connections are essential for managing the stress caused by expansion, contraction, misalignment, and vibrations resulting from mechanical operations and acoustical movements.

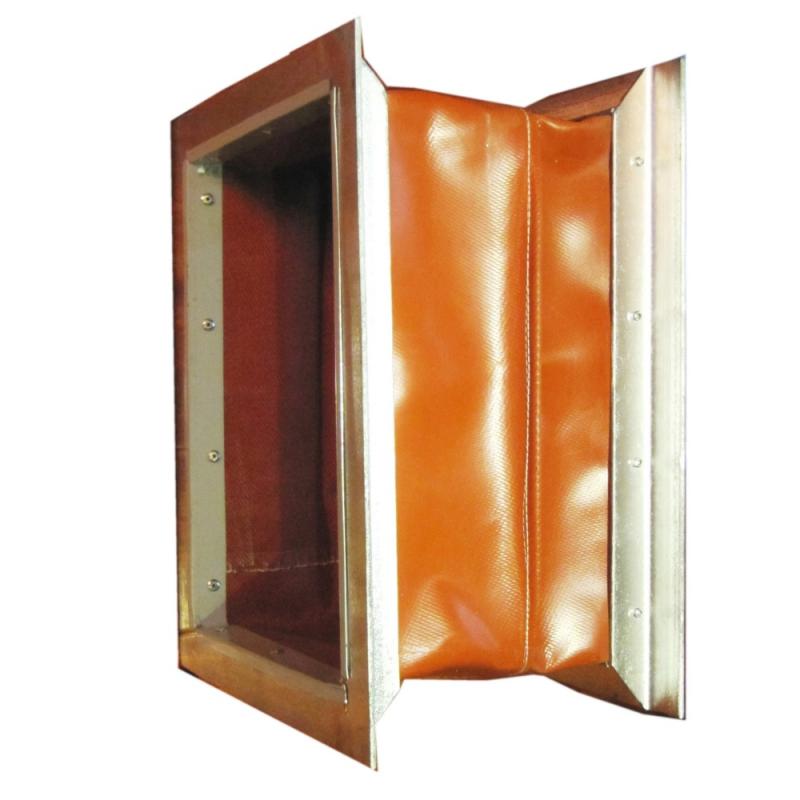

Construction and Materials: Fabric Expansion Joints are manufactured using high-grade synthetic materials, elastomers, and asbestos-free fabrics, ensuring safety and reliability. Their construction typically features multiple layers, including reinforcing glass fabric in the flange area and silicone-coated glass fabric for ambient protection. Some designs incorporate PTFE foil as an acid barrier, while glass or ceramic fibers provide temperature protection. This multi-layer approach allows the joints to handle a wide range of temperatures and movements effectively.

Design Versatility: One of the key advantages of Fabric Expansion Joints is their design flexibility. They can be tailored to meet specific shapes, sizes, and operating conditions. The construction can vary to accommodate different temperature ranges, movement types, and installation requirements. Stainless steel wire mesh is often included to maintain the joint's shape and facilitate easy installation and maintenance.

Applications: Fabric Expansion Joints are primarily employed in various industries, including:

- Gas Turbine Plants: They effectively manage thermal expansion and vibrations in turbine systems, ensuring smooth operation.

- Power Generation Facilities: Used in boiler systems and diesel-powered plants, these joints handle the unique challenges presented by high-temperature gases and fluctuations.

- Cement Industry: They accommodate the movements in ductwork associated with dust and particulate flow.

- Chemical and Petrochemical Industries: Fabric Expansion Joints resist aggressive and abrasive gases, ensuring safe and efficient operation in challenging environments.

- Metallurgical and Smelter Industries: Their ability to handle high temperatures and corrosive conditions makes them ideal for this sector.

Advantages of Fabric Expansion Joints:

- Large Movement Compensation: Fabric Expansion Joints can accommodate significant movements in a compact space, making them ideal for various installations.

- Multi-Plane Absorption: They absorb simultaneous movements across multiple planes, effectively reducing stress on connected piping and duct systems.

- Low Forces Required: Very low forces are necessary to initiate movement in the expansion joint, allowing for smoother operation.

- Noise and Vibration Resistance: These joints help mitigate noise and vibrations, enhancing operational comfort and safety.

- Corrosion Resistance: The materials used are resistant to corrosion, ensuring longevity and reliability in demanding environments.

- Easy Installation and Maintenance: Their lightweight design simplifies installation and reduces maintenance requirements.

- Cost-Effective Replacement: Fabric Expansion Joints offer a low-cost replacement option compared to traditional metallic joints.

- Design Freedom: Manufacturers can customize these joints to meet specific application needs, providing optimal solutions for various systems.

- Thermal Breaks: They act as thermal breaks, reducing the transmission of heat through the joints, which is essential in temperature-sensitive applications.

In collaboration with clients, SEIRIS specializes in providing tailored Fabric Expansion Joint solutions that meet the specific needs of various applications. By understanding the unique challenges presented by each installation, SEIRIS ensures that customers receive the most effective and reliable expansion joint solutions for their operational requirements. Whether for power generation, chemical processing, or any other industrial application, Fabric Expansion Joints offer flexibility, durability, and efficiency in managing thermal and mechanical movements.

IPv6 network supported

IPv6 network supported