Silicone Coated Fiberglass Tape for High Temperature Insulation and Sealing

Product Overview

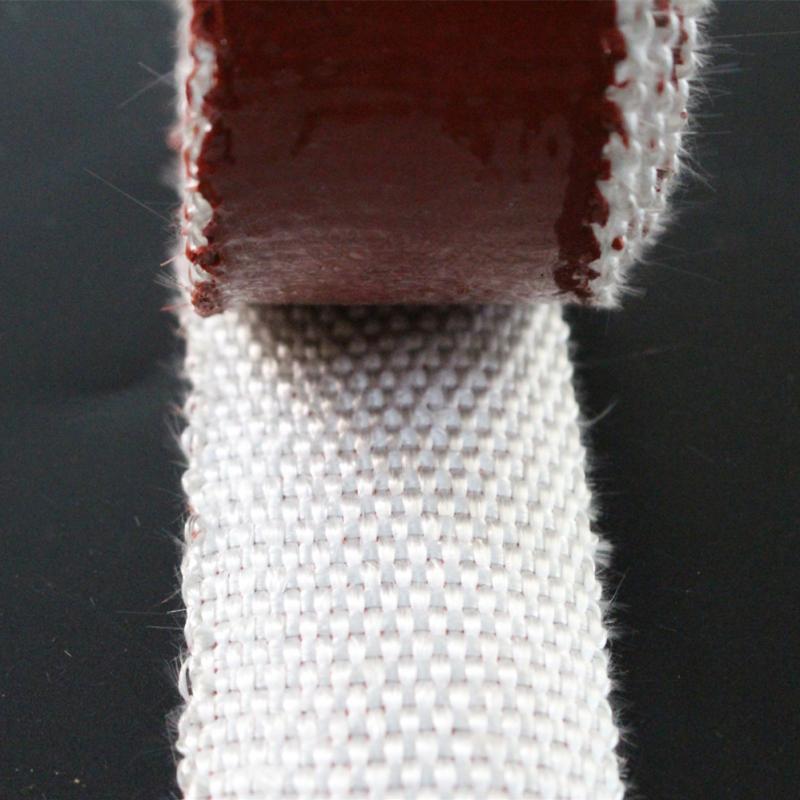

Silicone coated fiberglass tape is a high-temperature insulation and protection material developed for industrial applications where heat resistance, flexibility, and environmental durability are required. It is manufactured from woven fiberglass fabric coated with silicone rubber, combining the thermal stability and mechanical strength of fiberglass with the surface protection and flexibility provided by silicone.

This tape is commonly used to wrap, insulate, and protect hoses, pipes, cables, and components exposed to elevated temperatures, moisture, vibration, and mechanical contact in industrial environments.

Material Construction

The product consists of two functional layers:

-

Fiberglass base fabric

Provides mechanical strength, dimensional stability, and resistance to elevated temperatures.

-

Silicone rubber coating

Improves surface durability, flexibility, and resistance to moisture, oil splash, and environmental exposure while reducing fiberglass fraying during installation.

This construction allows the tape to perform reliably under repeated wrapping and long-term service conditions.

Typical Applications

Silicone coated fiberglass tape is widely used in:

-

Thermal insulation of hoses, pipes, and tubing

-

Wrapping and protection of electrical wiring and cable assemblies

-

Sealing and insulation in engines, generators, and industrial equipment

-

Protection of joints, flanges, and irregular components

-

Maintenance, repair, and retrofit operations

These applications are commonly found in industrial manufacturing, power generation, automotive, marine, and heavy equipment environments, where continuous heat exposure and environmental stress are present.

Performance Characteristics

-

Designed for continuous exposure to elevated temperatures

-

Silicone surface resists moisture, oil splash, and many industrial fluids

-

Maintains flexibility for wrapping around complex or irregular shapes

-

Non-conductive materials provide electrical insulation properties

-

Suitable for both indoor and outdoor industrial use

Engineering Considerations

Heat Exposure

The fiberglass substrate provides stable thermal performance, while the silicone coating protects the surface from degradation caused by heat and environmental exposure.

Mechanical Handling

Compared to uncoated fiberglass tape, the silicone-coated surface improves abrasion resistance and durability during repeated handling, installation, and maintenance work.

Environmental Resistance

Silicone rubber offers good resistance to UV exposure, moisture, and weathering, supporting long-term use in demanding industrial environments.

Technical Specifications

| Item |

Description |

| Base Material |

Woven fiberglass |

| Coating |

Silicone rubber |

| Form |

Tape |

| Color |

Commonly red (custom colors available) |

| Temperature Resistance |

Suitable for high-temperature insulation |

| Electrical Properties |

Non-conductive |

| Application Method |

Wrap or bind |

Installation & Use

-

Wrap the tape tightly around the component requiring insulation or protection

-

Overlap layers as needed to achieve the desired insulation thickness

-

Secure tape ends mechanically or with compatible fastening methods if required

-

Avoid excessive tension that may distort the fiberglass weave

Limitations

-

Not intended for direct flame exposure without additional fire protection

-

Not designed as a pressure-containing or structural reinforcement material

-

Chemical compatibility should be verified for aggressive fluids or solvents

For applications involving direct flame, molten metal, or extreme heat exposure, additional fire-resistant protection should be considered.

RFQ Information

To provide accurate pricing and lead time, please include the following information when submitting your inquiry:

-

Application type (insulation, wrapping, sealing, protection)

-

Continuous and peak operating temperature

-

Required tape width, thickness, and roll length

-

Component or substrate being wrapped

-

Operating environment (indoor/outdoor, moisture, oil, vibration)

-

Estimated quantity or annual usage

Providing complete application details helps ensure proper material selection and reliable long-term performance.

Use Recommendation

Silicone coated fiberglass tape is recommended for high-temperature insulation, wrapping, and sealing applications where flexibility, environmental resistance, and dependable thermal performance are required.

Technical Documentation

Technical Overview – Silicone Coated Fiberglass Tape (PDF)

This Technical Overview provides engineering-level information on material construction, thermal performance, application conditions, installation considerations, and RFQ requirements for silicone coated fiberglass tape used in industrial environments.

Download Technical Overview (PDF)

Different kinds of fiberglass tapes,

Other kinds of heat insulation tape,

IPv6 network supported

IPv6 network supported