- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Mail Us: vanessa-cheng@live.cn

- Call Us: +86 15856303740

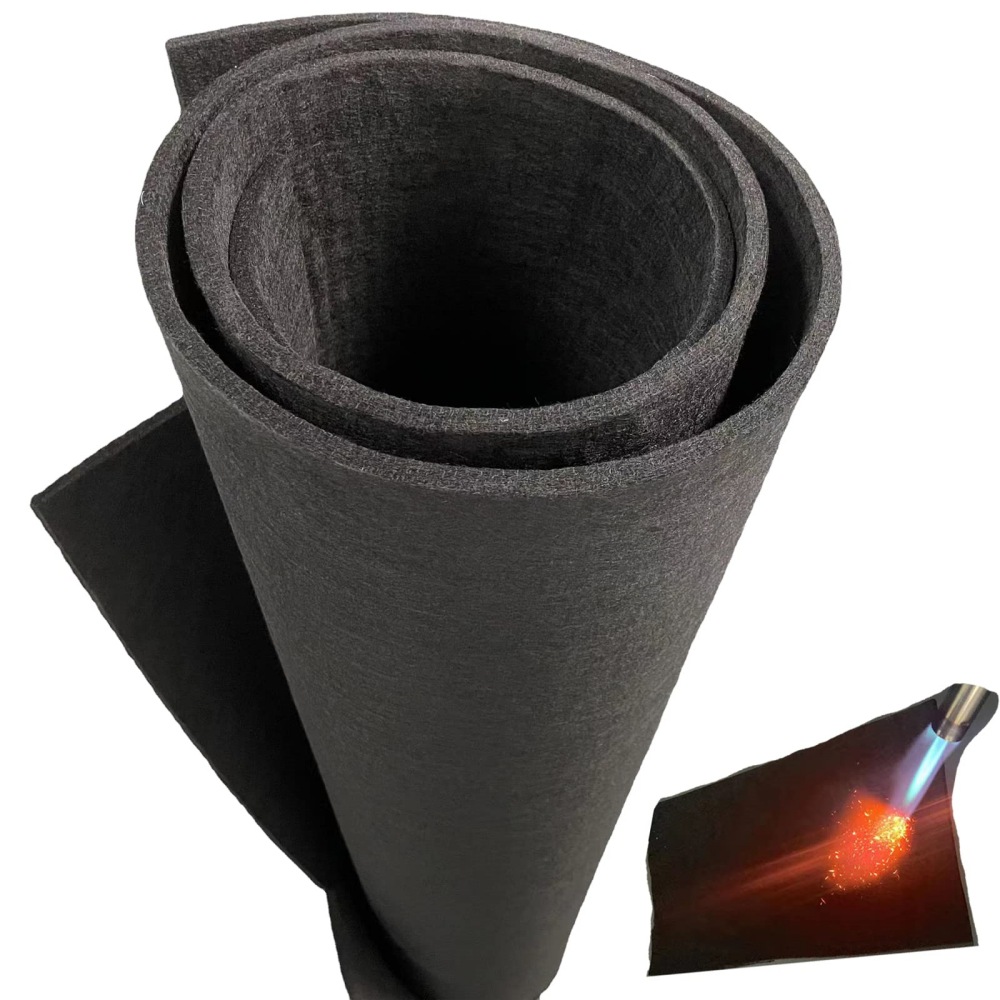

A Carbon Fiber Welding Blanket is a high-performance thermal protection solution engineered for extreme welding and metalworking environments. Designed to withstand intense radiant heat, sparks, and molten metal splash, it provides a reliable protective barrier for equipment, work surfaces, and personnel operating in high-temperature conditions.

Unlike conventional welding blankets made from fiberglass or treated fabrics, carbon fiber welding blankets deliver superior heat stability, mechanical strength, and service life. They are widely adopted in industrial fabrication, heavy manufacturing, shipbuilding, and high-risk welding zones where standard materials fail prematurely.

During welding, cutting, or grinding, temperatures can rise rapidly and generate uncontrolled sparks and slag. A Carbon Fiber Welding Blanket functions as a thermal shield by:

Absorbing and dispersing radiant heat

Blocking direct flame and molten metal contact

Preventing heat transfer to underlying structures

Reducing ignition risk of nearby materials

The inherent thermal stability of carbon fiber allows the blanket to maintain structural integrity under repeated exposure to extreme heat, ensuring consistent protection throughout long welding cycles.

Carbon fiber materials tolerate continuous high temperatures and short-term thermal peaks without melting or degrading, making the blanket suitable for demanding welding operations.

A Carbon Fiber Welding Blanket does not ignite, drip, or propagate flames, significantly reducing fire hazards in confined or enclosed workspaces.

Carbon fiber offers outstanding tensile strength and abrasion resistance, preventing tearing or fraying even under heavy industrial use.

Despite its strength, the blanket remains flexible and easy to handle, allowing quick positioning around complex components, pipes, or machinery.

A Carbon Fiber Welding Blanket is commonly used across multiple industries:

Industrial welding and metal fabrication workshops

Automotive and heavy-duty equipment manufacturing

Shipyards and offshore platforms

Power plants and boiler maintenance

Pipeline welding and structural steel work

Aerospace component fabrication

In these environments, reliable thermal protection is essential not only for safety but also for preventing costly equipment damage and downtime.

Compared with fiberglass or standard fire-resistant welding blankets, carbon fiber solutions provide measurable advantages:

Higher continuous temperature tolerance

Longer service life under repeated heat exposure

Improved resistance to sparks and molten slag

Reduced fiber breakdown and airborne irritation

Lower long-term replacement cost

For operations that demand consistent performance and minimal maintenance, a Carbon Fiber Welding Blanket represents a more durable and economical choice.

When choosing a Carbon Fiber Welding Blanket, consider the following factors:

Temperature Rating

Ensure the blanket meets or exceeds the maximum radiant and contact heat generated during your welding process.

Size and Coverage Area

Select dimensions that fully protect surrounding equipment, floors, walls, or operators.

Thickness and Weight

Thicker blankets offer enhanced insulation, while lighter versions improve handling and flexibility.

Customization Options

Many industrial users require custom sizes, reinforced edges, grommets, or tailored shapes to match specific applications.

For optimal performance and safety:

Position the blanket securely to avoid movement during welding

Avoid sharp folds that may concentrate heat in one area

Keep the blanket clear of oil, grease, or chemicals

Inspect regularly for mechanical damage or excessive wear

Proper handling extends the working life of the Carbon Fiber Welding Blanket and ensures consistent protection.

Investing in a Carbon Fiber Welding Blanket delivers more than short-term protection. It contributes to:

Improved workplace safety compliance

Reduced fire incidents and liability risks

Lower replacement frequency compared to traditional blankets

Increased productivity by minimizing heat-related interruptions

For professional welding environments, carbon fiber welding blankets are a strategic safety asset rather than a consumable accessory.

A Carbon Fiber Welding Blanket provides ultimate protection for high-temperature welding applications where safety, durability, and performance cannot be compromised. With superior heat resistance, fire safety, and mechanical strength, it is the preferred solution for industrial welding professionals seeking reliable, long-lasting thermal protection.

Whether used in fabrication shops, shipyards, or heavy industry, carbon fiber welding blankets help safeguard personnel, protect equipment, and maintain operational efficiency in extreme thermal conditions.

IPv6 network supported

IPv6 network supported