High-Performance Injection Machine Barrel Insulation Blanket

Advanced Thermal Control for Injection and Extrusion Equipment

Product Description

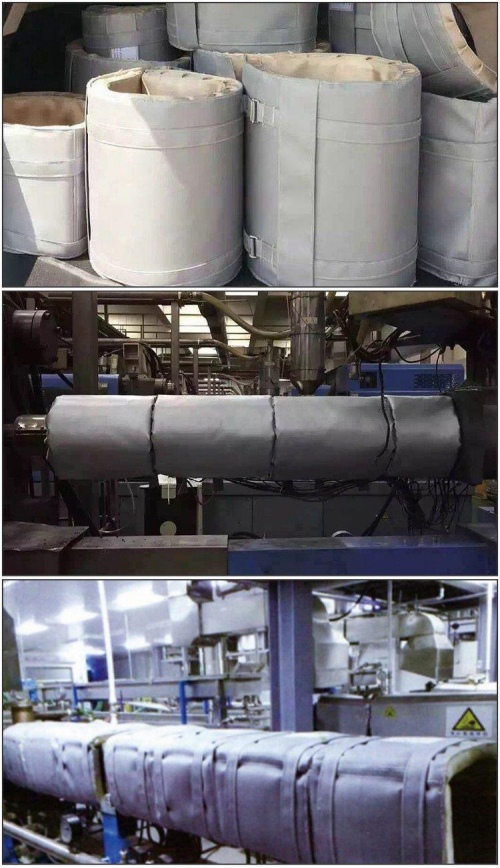

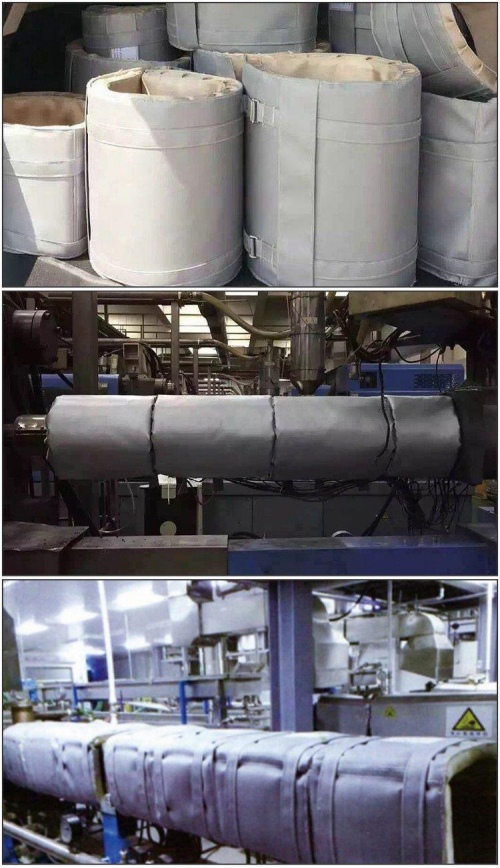

The Injection Machine Barrel Insulation Blanket is a high-performance thermal insulation system engineered to reduce energy loss and enhance thermal regulation in industrial molding and extrusion environments. Designed to wrap around heated components such as injection barrels, extruder pipes, and die heads, this multi-layered insulation solution traps radiant heat, delivering superior temperature consistency and operational efficiency.

Also known as Barrel Insulation Jacket, Barrel Blanket for Injection Barrels, or Injection Machine Barrel Insulation Cover, this product is widely used in injection molding, extrusion, and blow molding processes. Its modular construction and flexible installation system make it a practical choice for both OEMs and retrofit applications.

Technical Features

-

Multi-Layer Insulation Construction:

Built with a durable silicone-coated fiberglass exterior, a 25mm thick ceramic fiber insulation core, and a high-temperature fiberglass inner layer, each insulation blanket offers long-term resistance to extreme heat, chemicals, and mechanical stress.

-

Thermal Resistance Performance:

-

Outer Layer: Silicone-coated fiberglass (rated up to 260°C contact)

-

Insulation Core: Ceramic fiber blanket (excellent for sustained high-temperature performance)

-

Inner Layer: Fiberglass cloth (rated up to 550°C contact)

-

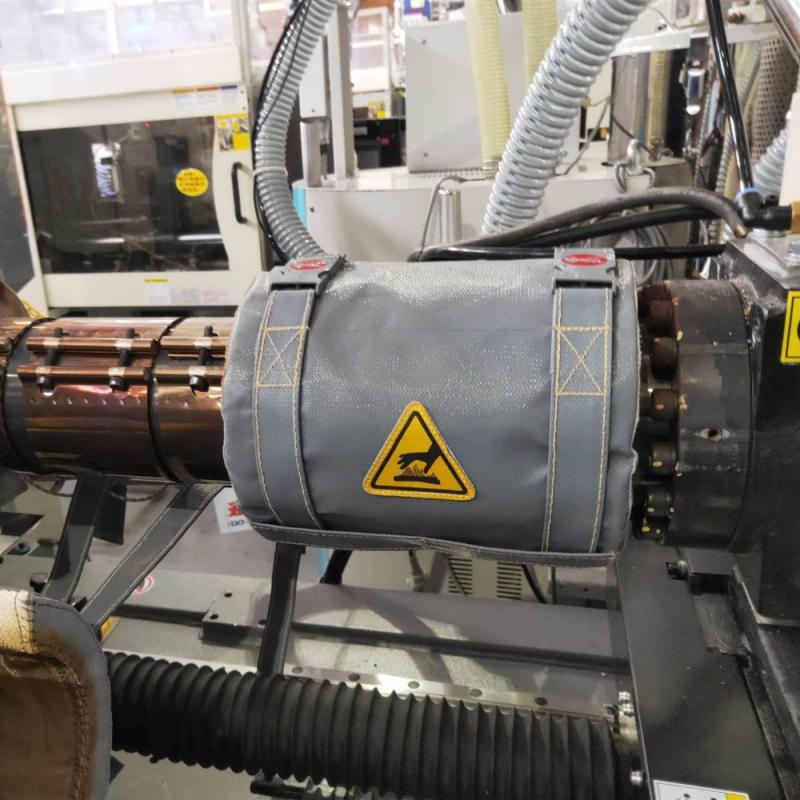

Secure Fastening System:

Hook-and-loop Velcro closures paired with heavy-duty buckles ensure a tight, safe fit and allow for quick removal or reinstallation during maintenance.

-

Custom-Fit Sizing:

Designed to meet exact machine dimensions, with options from 13″ to 44″ in circumference and 2″ to 37″ in width. Precision adjustments and custom cutouts available for no-compromise installation.

Functional Benefits

-

Energy Efficiency Up to 60%:

Minimizes heat dissipation to ambient air and returns energy back to the system, cutting power consumption significantly.

-

Faster Heat-Up Cycles:

Improves machine responsiveness during startup, contributing to shorter cycle times and higher throughput.

-

Improved Process Control:

Enables better regulation of barrel temperature zones, leading to improved product consistency and reduced scrap rates.

-

Protection & Safety Compliance:

The insulation layer minimizes the risk of contact burns and supports compliance with industrial safety regulations for high-temperature surfaces.

-

Extended Equipment Life:

Reduces thermal fatigue on heater bands and barrel surfaces, lowering maintenance frequency and associated costs.

-

Ambient Heat Reduction:

Contributes to a cooler, safer, and more comfortable working environment by limiting radiant heat escape from machine surfaces.

Industrial Applications

The Injection Molding Barrel Insulation system is ideal for use in:

-

Injection mold machines

-

Extrusion machines and barrel assemblies

-

Melt pipes and transfer lines

-

Blow molding dies

-

Structural foam molding equipment

-

High-heat industrial machinery requiring thermal retention

Why Choose Injection Machine Insulation Blankets?

Choosing the Injection Machine Insulation Blanket means adopting a proactive approach to thermal efficiency. Beyond energy savings, it creates a more stable process environment, reduces workplace hazards, and helps facilities meet energy reduction targets. Whether you require a standard solution or a custom-engineered configuration, these blankets can be adapted to suit any application with precision.

IPv6 network supported

IPv6 network supported