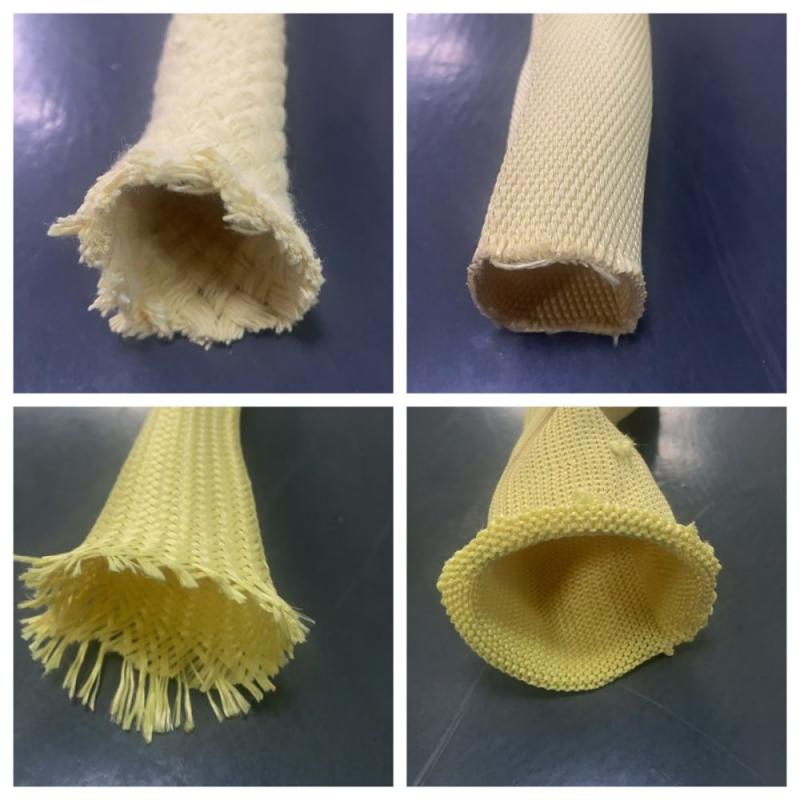

Flat Woven Kevlar Sleeve

Flat Woven Kevlar Sleeve is a hollow, flat-formed protective sleeve manufactured from aramid (Kevlar®) fibers using a woven construction. Unlike conventional round braided or knitted sleeves, this product is produced in a flat tubular shape, allowing wide surface coverage while retaining the ability to open and wrap around components.

With flat widths available from 10 mm up to 500 mm, this sleeve is designed for applications where large-area protection, surface isolation, or mechanical buffering is required rather than point protection.

Woven Construction and Flat Tubular Form

The sleeve is manufactured using a woven textile process that forms a hollow, flattened tube.

-

Woven structure provides dimensional stability across wide widths

-

Flat tubular form allows the sleeve to cover large contact areas

-

Hollow construction enables wrapping, folding, or opening during installation

-

Maintains flexibility without collapsing or twisting

Compared with knitted or braided Kevlar sleeves, the flat woven structure offers better surface consistency and width control, especially in wide-format applications.

Mechanical and Material Performance

Flat Woven Kevlar Sleeve is primarily selected for its mechanical protection capability and material stability.

-

High tensile strength at low weight

-

Excellent resistance to cutting and surface abrasion

-

Low elongation under load, providing structural rigidity

-

Low electrical conductivity

-

Low thermal shrinkage

-

Flame resistant and self-extinguishing

-

Maintains dimensional stability under continuous use

Kevlar fibers provide outstanding toughness and durability, while the woven structure distributes mechanical stress evenly across the sleeve surface.

Temperature Resistance

The sleeve is suitable for elevated temperature environments where mechanical protection and thermal stability are required.

-

Resistant to heat exposure in industrial environments

-

Does not melt or drip when exposed to flame

-

Maintains shape and performance at elevated temperatures

It is commonly used in applications involving hot surfaces, thermal cycling, or proximity to heat sources, where polymer-based sleeves would degrade.

Wide Width Capability (10–500 mm)

One of the key advantages of Flat Woven Kevlar Sleeve is its wide flat width production range.

-

Flat widths from 10 mm to 500 mm available

-

Suitable for narrow line protection as well as wide-area coverage

-

Can replace multiple narrow sleeves or stitched fabric layers

-

Reduces installation complexity and material overlap

This makes it particularly suitable for applications requiring uniform protection across large surfaces.

Typical Applications

Flat Woven Kevlar Sleeve is widely used in applications where surface protection, abrasion resistance, or thermal buffering is required:

-

Glass manufacturing and processing lines

Used as Kevlar roller sleeves or protective padding to prevent glass scratching, impact damage, and cold shock during furnace cooling stages

-

Industrial equipment and machinery

Surface protection for moving parts, guides, rollers, and contact zones

-

Marine and shipbuilding applications

Abrasion protection in high-load and harsh environments

-

Electrical and engineering systems

Mechanical protection where low electrical conductivity is required

-

Suspension, slings, and research equipment

Protective layers for components exposed to wear or repeated contact

Installation and Handling

-

Can be supplied in continuous lengths or cut pieces

-

Easily wrapped around rollers, shafts, hoses, or flat surfaces

-

Can be fixed using clamps, stitching, or mechanical fastening depending on application

-

Flat structure allows precise positioning without rolling or bunching

Why Choose Flat Woven Kevlar Sleeve

Flat Woven Kevlar Sleeve is selected when applications require:

-

Wide-area protection rather than round point coverage

-

High cut and abrasion resistance

-

Stable dimensions across large widths

-

Long service life in mechanically demanding environments

It is not designed as a compression-bearing component, but as a durable protective and buffering layer.

Contact Us

If your application requires wide-format Kevlar protection, surface buffering, or abrasion resistance in high-temperature or mechanically demanding environments, Flat Woven Kevlar Sleeve offers a practical and reliable solution.

IPv6 network supported

IPv6 network supported