Kevlar Braided Sleeve for Abrasion Protection is a protective sleeving designed to reduce wear, cutting damage, and surface abrasion on hoses, cables, and wiring assemblies operating in mechanically demanding environments. The sleeve is constructed using braided aramid fibers, providing a balance of flexibility, strength, and long-term durability.

This product is primarily used in applications where mechanical abrasion, vibration, or repeated movement can lead to premature failure of unprotected components.

Material and Braided Structure

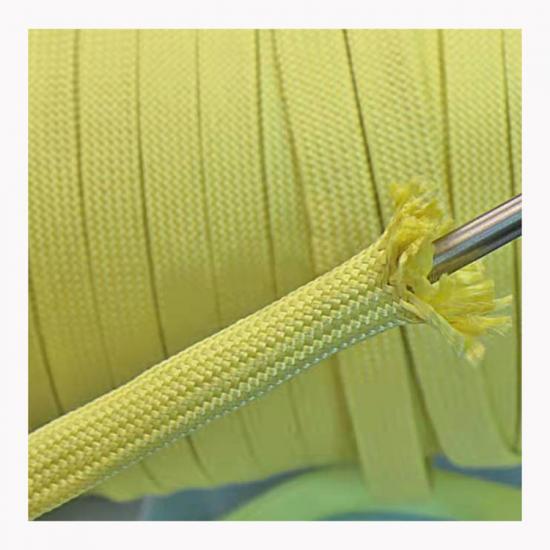

The sleeve is manufactured from aramid fibers arranged in a dense braided construction.

-

Aramid fibers are known for their high tensile strength and resistance to cutting

-

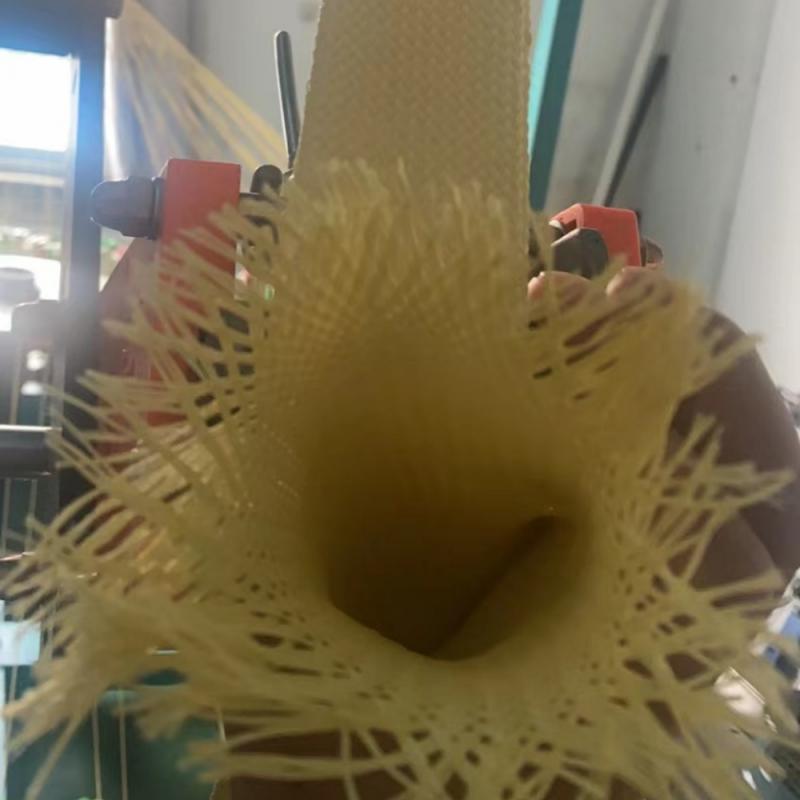

The braided structure allows the sleeve to expand and contract, accommodating different diameters

-

Maintains flexibility while providing consistent surface protection

This construction allows the sleeve to remain stable under continuous movement without becoming brittle or losing shape.

Abrasion and Wear Resistance

Kevlar Braided Sleeve is designed to perform in environments where surface contact and friction are unavoidable.

-

Reduces damage caused by rubbing against sharp edges or rough surfaces

-

Helps prevent wear from vibration and repeated motion

-

Protects hoses and cables from external mechanical stress

-

Extends service life of components exposed to abrasion

Rather than acting as a rigid barrier, the sleeve absorbs and distributes mechanical stress across the braided surface.

Key Characteristics

-

High resistance to abrasion and cutting

-

Braided structure allows flexibility and diameter adjustment

-

Lightweight design with minimal impact on system weight

-

Suitable for continuous dynamic movement

-

Maintains integrity in industrial and mobile environments

Typical Applications

Kevlar Braided Sleeve for Abrasion Protection is commonly used in:

-

Automotive and motorsport systems

Protection of hoses and wiring near moving or vibrating components

-

Industrial machinery

Cable and hose protection in areas with constant mechanical contact

-

Hydraulic and pneumatic systems

Prevention of wear on fluid lines subject to movement and friction

-

Aerospace and defense equipment

Abrasion protection where reliability and weight control are critical

Installation and Use

The braided sleeve can be installed by sliding it over hoses or cables prior to final assembly.

Its expandable structure allows it to fit securely without additional fastening in many applications.

For installations involving sharp edges or extreme abrasion, combining the sleeve with clamps or additional shielding may be recommended.

Why Choose Kevlar Braided Sleeve for Abrasion Protection

Compared with polyester or standard textile sleeves, aramid braided sleeves offer:

-

Higher resistance to cutting and surface wear

-

Greater durability under continuous mechanical stress

-

Reliable performance in applications with movement and vibration

It is selected when mechanical protection is the primary concern, rather than thermal insulation or cosmetic covering.

Contact Us

If abrasion, wear, or cutting damage is limiting the service life of your hoses or cables, Kevlar Braided Sleeve for Abrasion Protection provides a practical and durable solution.

IPv6 network supported

IPv6 network supported