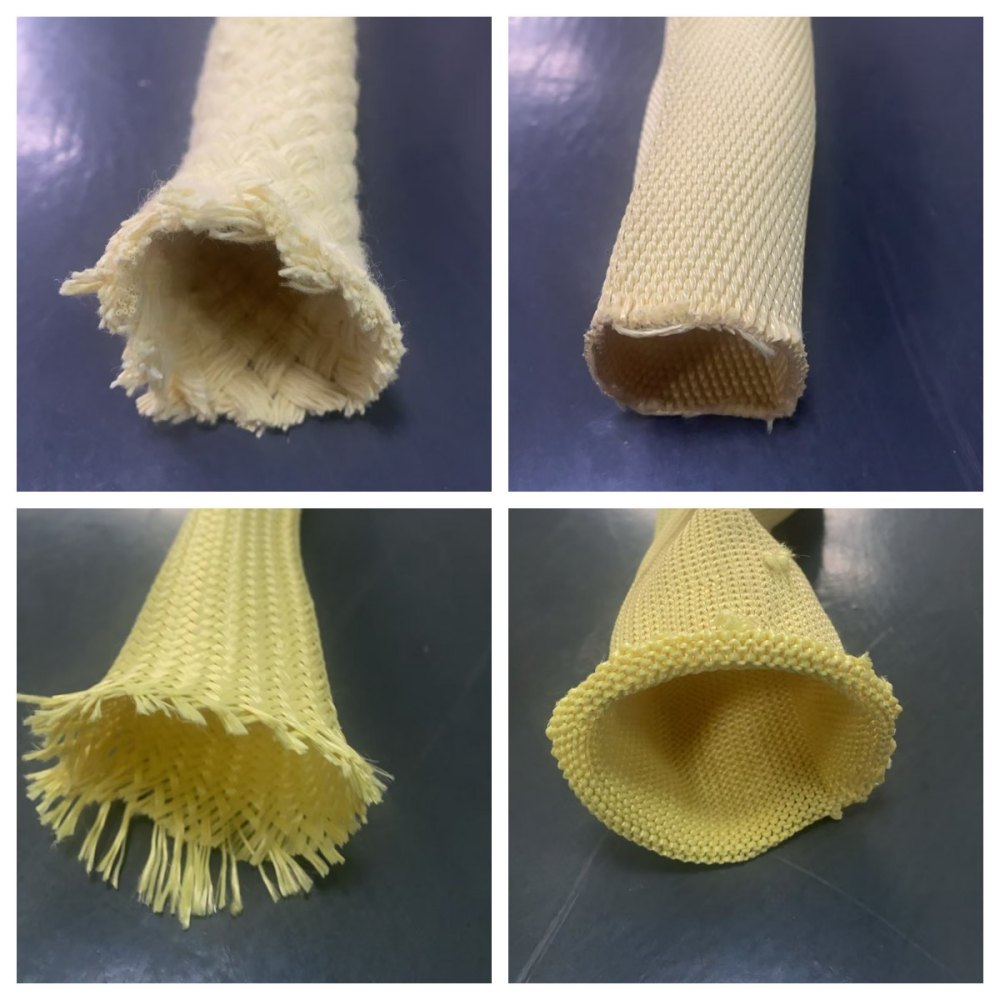

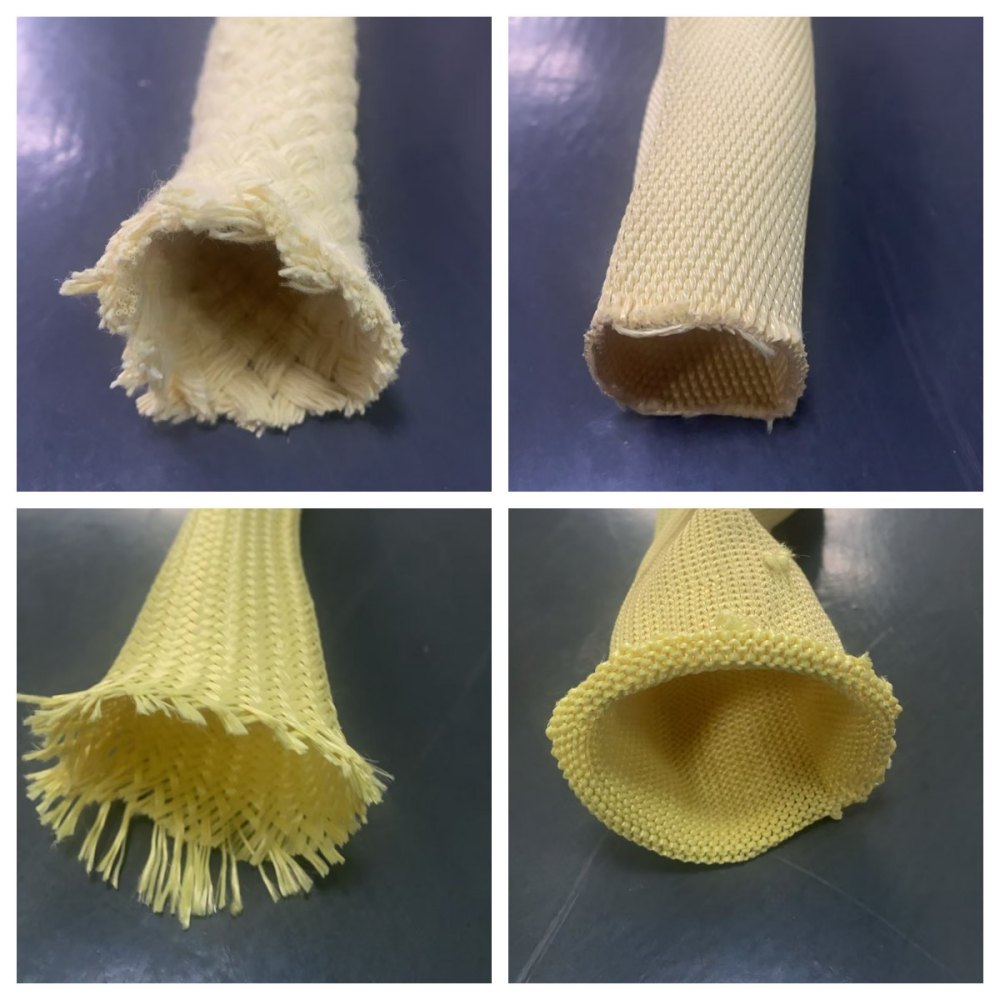

Knitted Kevlar Sleeve is a high-strength protective sleeve manufactured from aramid (Kevlar®) fibers using a knitted construction. It is designed for applications where resistance to cutting, abrasion, high temperature, and mechanical stress is required, while maintaining flexibility and dimensional stability.

This Kevlar sleeve is commonly used as Kevlar tubing sleeve, Kevlar roller sleeve, or Kevlar fabric sleeve in industrial environments where conventional textile sleeves are unable to withstand continuous mechanical and thermal loads.

Material and Knitted Structure

The sleeve is produced from continuous aramid fibers formed into a knitted tubular structure.

-

Knitted construction allows controlled flexibility and expansion

-

Aramid fibers provide high tensile strength at low weight

-

Maintains structural integrity under repeated mechanical stress

-

Suitable for static and dynamic applications

Compared with braided sleeves, the knitted structure offers improved surface conformity and stability when installed over rollers, tubes, or cylindrical components.

Mechanical and Thermal Performance

Knitted Kevlar Sleeve is selected primarily for its mechanical toughness and resistance to damage in harsh operating conditions.

-

High work-to-break toughness

-

High tensile strength with low elongation to break

-

High modulus provides structural rigidity

-

Excellent cut and wear resistance

-

Low electrical conductivity

-

Low thermal shrinkage

-

Flame resistant and self-extinguishing

-

Maintains dimensional stability at elevated temperatures

-

Critical temperature resistance up to 400°F (≈204°C)

While Kevlar offers exceptional tensile performance, it has relatively low compression strength, which should be considered in design and application selection.

Durability in Continuous Operation

The sleeve is engineered for long-term use in environments involving:

-

Repeated contact with hot or abrasive surfaces

-

Continuous motion or rotation

-

Mechanical loading without sharp compression

Its durability makes it suitable for industrial processes where downtime caused by sleeve failure is not acceptable.

Typical Applications

Knitted Kevlar Sleeve is widely used in demanding industrial and technical fields, including:

-

High-temperature operations

-

Glass manufacturing and processing lines

-

Special ship and marine engineering

-

Electrical engineering and insulation support

-

Suspension systems and slings

-

Research and experimental equipment

Glass Furnace Roller Protection (Kevlar Roller Sleeve Application)

In glass production lines operating at 200–500°C, molten or heated glass is transported through furnaces and cooling zones using metal rollers. Due to the large temperature difference between hot glass and cold metal rollers, direct contact can cause:

When Kevlar roller sleeves made from knitted Kevlar tubing are spirally installed over furnace rollers, they act as a thermal and mechanical buffer.

This prevents direct contact between glass and low-temperature metal surfaces, reduces surface defects, and improves finished glass yield.

Installation and Use

-

The sleeve can be cut to length and slid directly over rollers, tubes, or shafts

-

Knitted structure allows secure fitting without excessive tension

-

Suitable for spiral wrapping or straight installation depending on application

For applications involving high compression loads, additional structural support may be required.

Why Choose Knitted Kevlar Sleeve

Knitted Kevlar Sleeve is chosen when applications require:

-

High cut and abrasion resistance

-

Stable performance at elevated temperatures

-

Low weight with high tensile strength

-

Long service life in continuous industrial operation

It is not intended as a compression-bearing component, but as a mechanical and thermal protective layer.

Contact Us

If your application involves high temperature, abrasion, cutting risk, or sensitive surface protection, Knitted Kevlar Sleeve offers a reliable and proven solution.

IPv6 network supported

IPv6 network supported