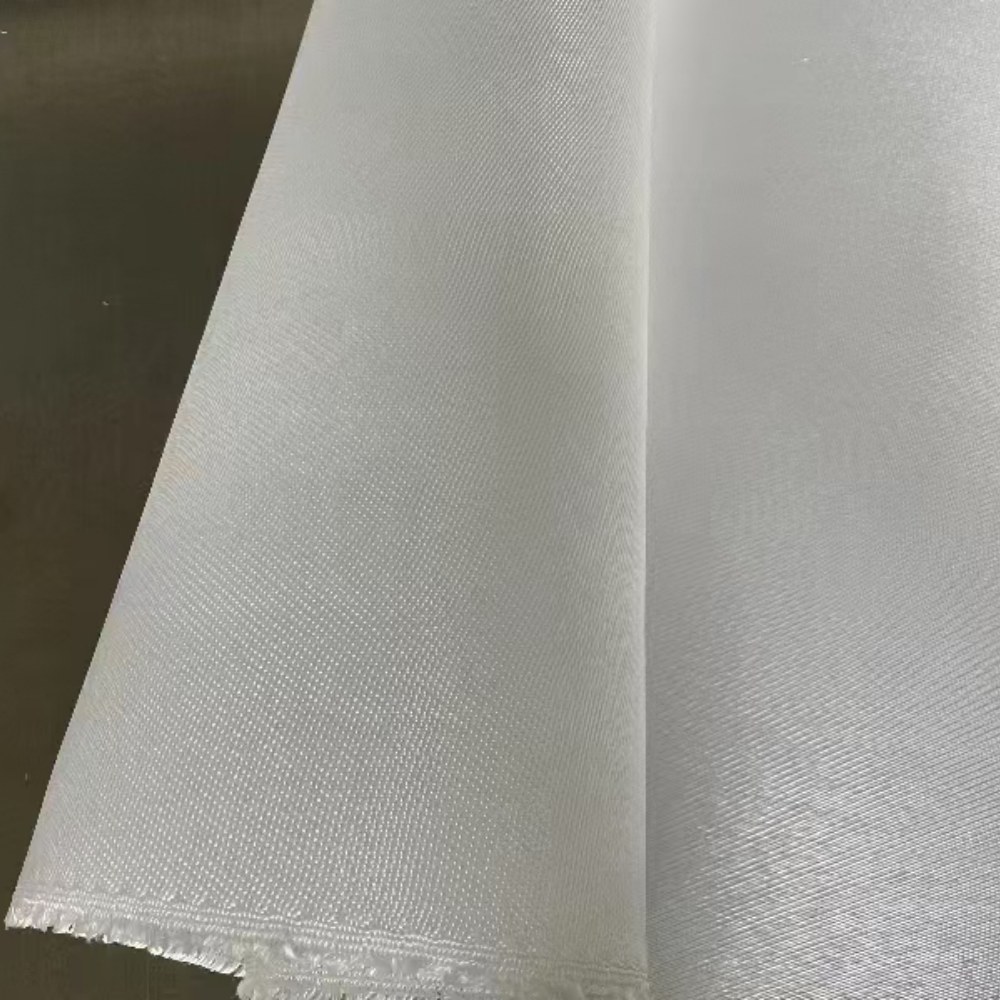

- Silicone Coated Fiberglass Fabric

- Fiberglass Welding Blanket Rolls

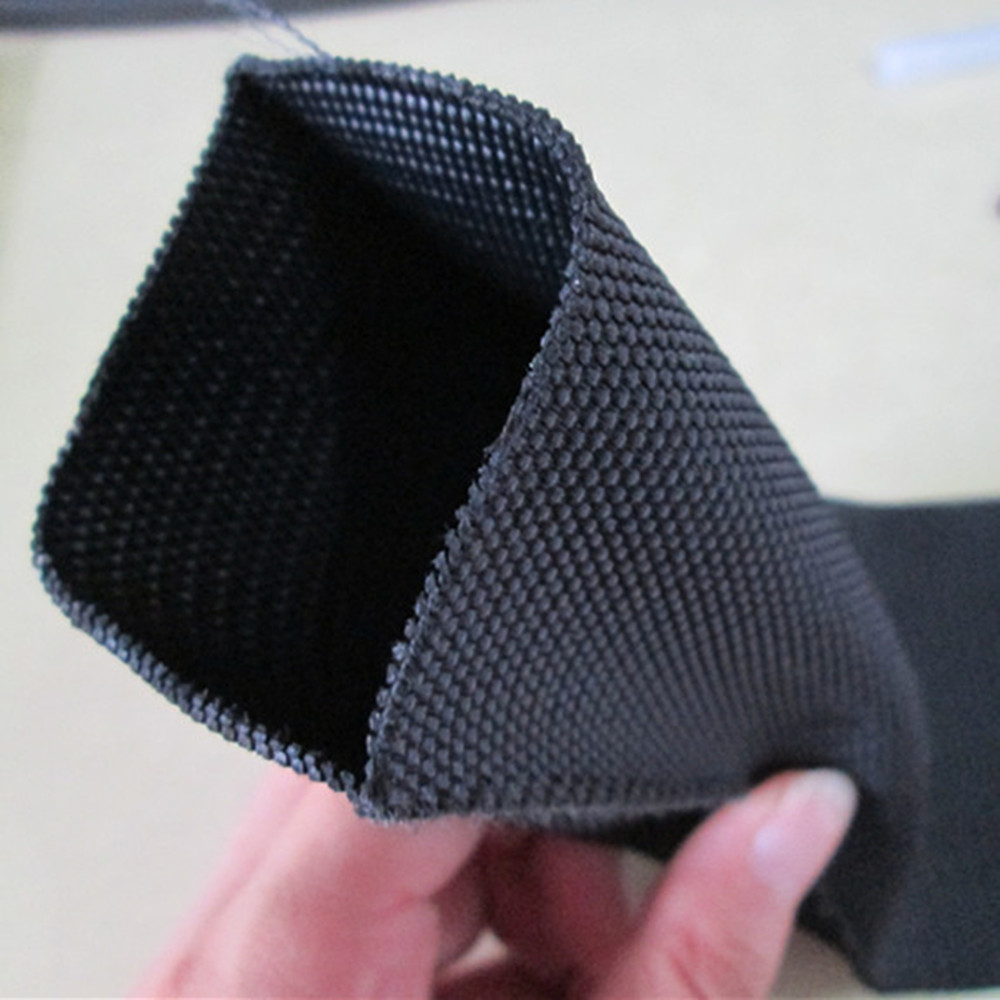

- Nylon Sleeve Hose Protector

- Hydraulic Hose Protection Sleeve

- Nylon Protective Sleeve for hose

- Hydraulic Hose Protective Fire Sleeve

- Fire Sleeve for Hose

- Hose Protective Fire Sleeve

- Ceramic Fiber Tape

- Fiberglass Needle Mat With Aluminium Foil

- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Mail Us: vanessa-cheng@live.cn

- Call Us: +86 15856303740

IPv6 network supported

IPv6 network supported