- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Mail Us: vanessa-cheng@live.cn

- Call Us: +86 15856303740

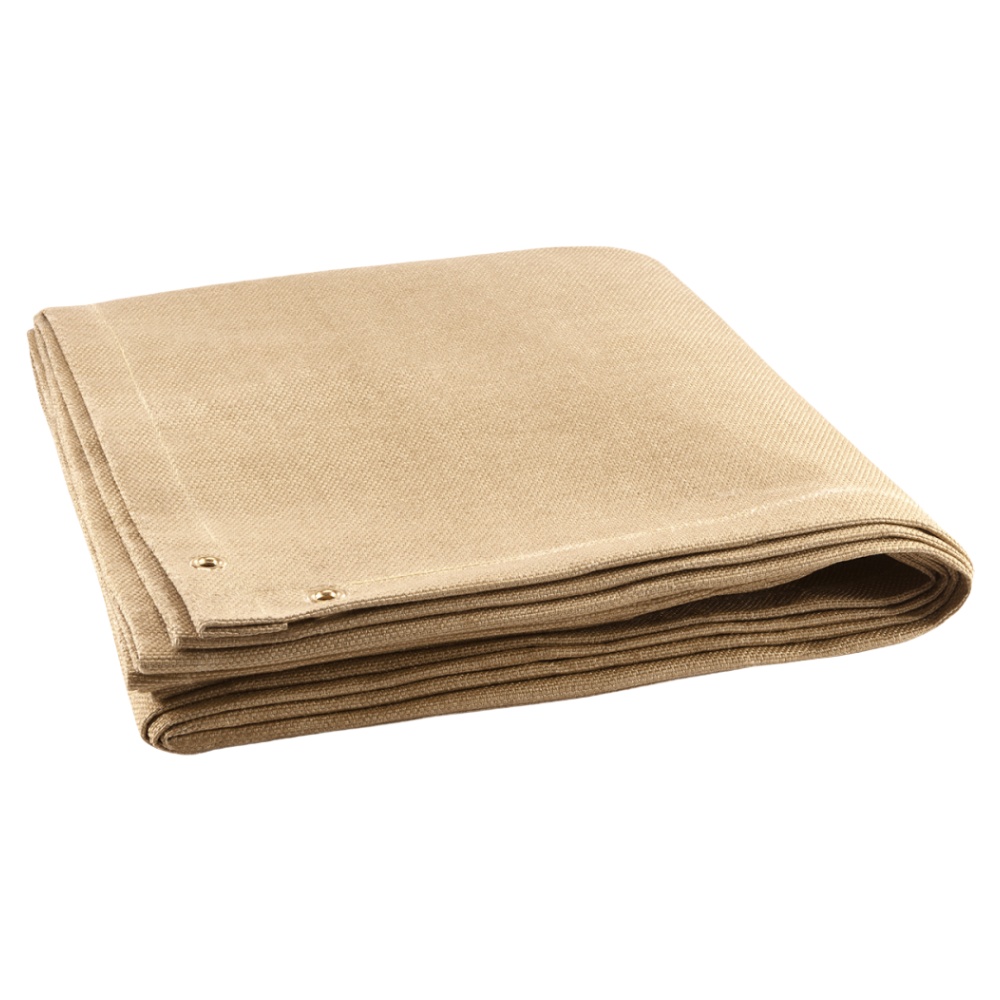

Uncoated Fiberglass Welding Blanket is designed to provide reliable protection against sparks, spatter, and moderate heat exposure during welding, cutting, and metal fabrication operations. Manufactured from woven fiberglass fabric without surface coatings, the blanket offers a practical balance of heat resistance, flexibility, and ease of handling for general-purpose industrial protection.

The blanket is suitable for horizontal or vertical applications and can be supplied with grommets for convenient hanging and positioning in welding environments.

Payment:

EXW, CIF, FOB, DDP, etcProduct Origin:

ChinaColor:

WhiteShipping Port:

Shanghai, NingboLead Time:

3-10 daysUncoated Fiberglass Welding Blanket is designed to provide reliable protection against sparks, spatter, and moderate radiant heat generated during welding, cutting, and metal fabrication operations. Manufactured from woven fiberglass fabric without surface coatings, this welding blanket offers excellent heat resistance, flexibility, and breathability for general-purpose industrial protection.

Uncoated fiberglass welding blankets are widely used in applications where effective spark and heat shielding is required without the need for additional surface treatments.

This welding blanket is produced from continuous fiberglass yarns woven into a durable and flexible fabric structure. The uncoated construction allows the material to maintain its natural heat resistance and permeability while remaining lightweight and easy to handle.

Key construction features include:

Woven fiberglass fabric without coatings

Inherent resistance to heat and flame

Flexible structure for easy draping and positioning

Good mechanical strength for repeated use

The absence of coatings makes this blanket suitable for applications where breathability and cost efficiency are important.

Uncoated fiberglass welding blankets are designed for protection against common welding hazards:

Effective shielding against sparks and welding spatter

Resistance to moderate radiant heat exposure

Stable performance under intermittent high-temperature conditions

Suitable for general welding and fabrication environments

For applications involving prolonged extreme heat or molten metal splash, coated or higher-performance blankets may be recommended.

Uncoated fiberglass welding blankets are commonly used in:

Welding and cutting operations

Metal fabrication and maintenance work

Grinding and repair activities

Protection of equipment, floors, and surrounding surfaces

General industrial heat and spark protection

They are widely used in workshops, factories, shipyards, and construction sites.

| Item | Description |

|---|---|

| Base material | Fiberglass |

| Surface treatment | Uncoated |

| Construction | Woven fabric |

| Blanket thickness | Customized upon request |

| Areal weight | Customized upon request |

| Standard size | Customized upon request |

| Heat resistance | Suitable for welding and spark protection |

| Flame resistance | Inherent |

| Flexibility | Flexible and easy to drape |

Blanket can be draped or positioned over work areas and equipment

Can be cut to size using standard cutting tools

Avoid direct contact with molten metal without additional protection

Protective gloves are recommended during handling

Proper placement ensures effective protection and longer service life.

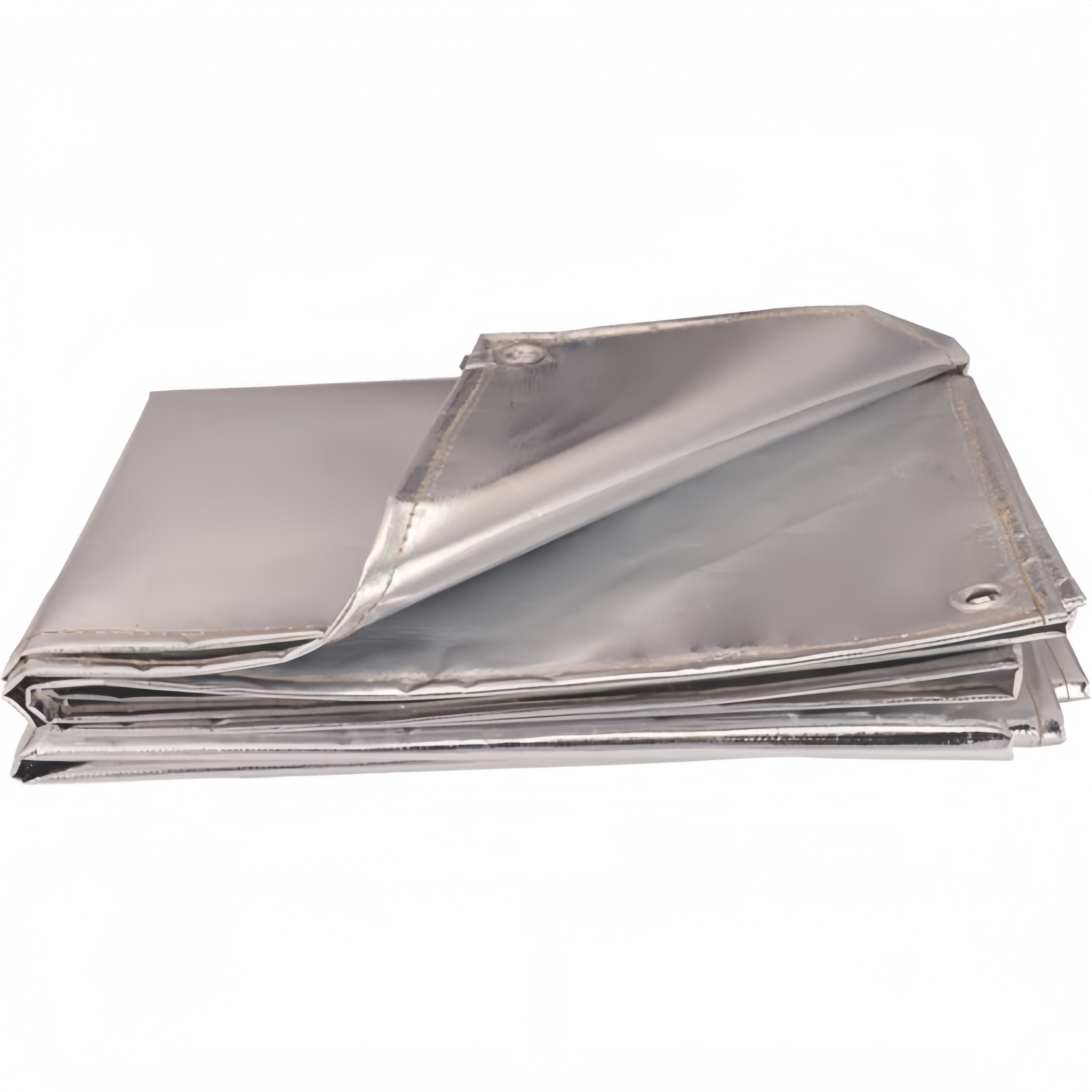

Compared with coated welding blankets, uncoated fiberglass blankets offer:

Lightweight and easy handling

Good breathability

Cost-effective protection for general welding tasks

Flexible fabric suitable for various applications

These advantages make them a practical choice for everyday welding protection.

Not intended for prolonged exposure to extreme radiant heat

Not suitable for direct molten metal contact

Performance depends on correct application and exposure conditions

Selection should be based on actual welding environment and protection requirements.

To receive accurate pricing and technical support, please provide the following information when submitting an inquiry:

Application type and working environment

Required blanket dimensions and quantity

Expected heat exposure level

Frequency of use

Blanket size, thickness, and fabric weight can be customized according to specific application requirements.

Uncoated Fiberglass Welding Blanket is recommended for general welding, cutting, and fabrication applications requiring dependable spark and heat protection, especially where lightweight handling and cost efficiency are important.

Technical Overview – Uncoated Fiberglass Welding Blanket (PDF)

This Technical Overview provides engineering-level information on material construction, thermal performance, mechanical characteristics, application conditions, and RFQ requirements for uncoated fiberglass welding blankets used in industrial welding and fabrication environments.

Related product page:

Download Technical Overview (PDF)

| Fabric you can choose from BSTFLEX | Types of welding |

| Uncoated fiberglass welding blanket | Light, middle, heavy welding sparks |

| Heat treated fiberglass welding blanket | Light, middle, heavy welding sparks |

| PVC coated fiberglass welding blanket | Light welding sparks |

| Silicone coated fiberglass welding blanket | Light, middle, heavy welding sparks |

| Acrylic coated fiberglass welding blanket | Middle welding sparks |

| Silica fiber welding blanket | Heavy, Extreme heavy welding sparks |

| Silicone coated silica welding blanket | Heavy, Extreme heavy welding sparks |

| Vermiculite coated fiberglass welding blanket | Heavy, Extreme heavy welding sparks |

| Triple layer fiberglass welding blanket | Extreme heavy welding sparks |

| Carbon fiber welding blanket | Extreme heavy welding sparks |

| Size: 4'X6', 6' X 6', 6' X 8', 8' X 8', 10' X 10', 1m width X 50m roll length, or customized | |

Other Welding blankets & Welding blanket rolls products: