- NINGGUO BST THERMAL PRODUCTS CO., LTD.

- Mail Us: vanessa-cheng@live.cn

- Call Us: +86 15856303740

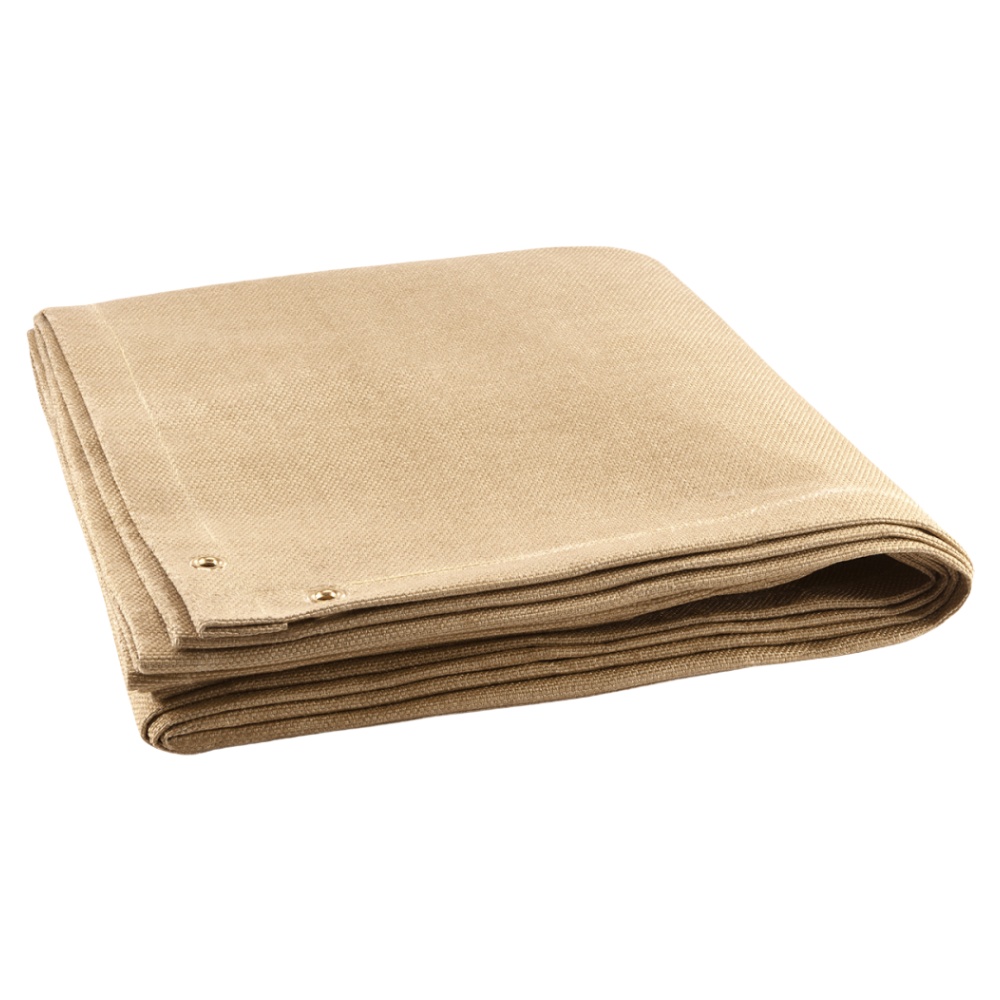

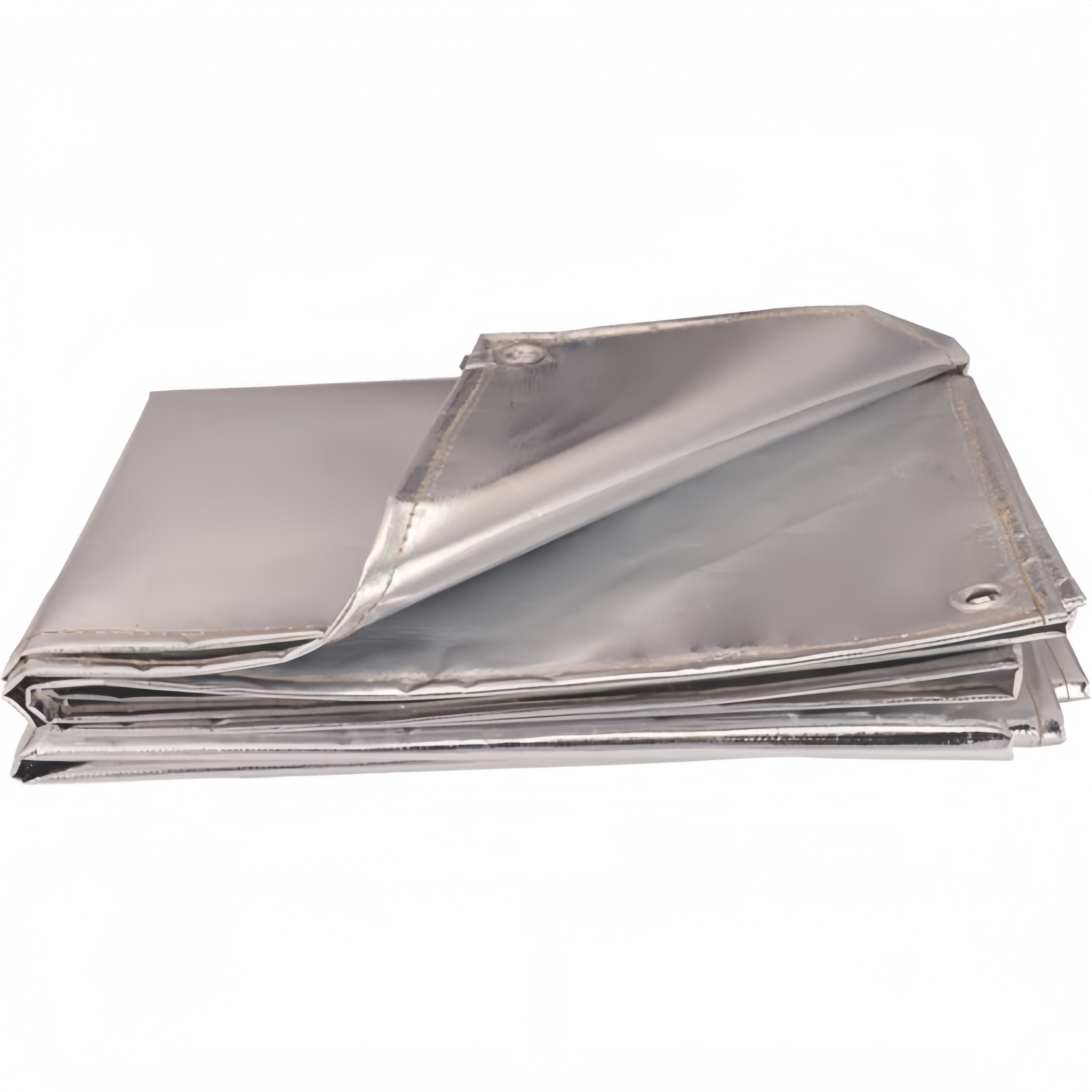

The Acrylic Coated Fiberglass Welding Blanket is designed to provide reliable protection against welding sparks, spatter, and radiant heat during hot work operations. Manufactured from woven fiberglass fabric with a durable acrylic coating, this blanket offers enhanced surface strength, flexibility, and resistance to mechanical wear.

It is widely used in welding, cutting, and fabrication environments to protect equipment, work surfaces, and surrounding areas. Compared with uncoated fiberglass materials, the acrylic coating improves durability and handling performance, making this welding blanket a practical and cost-effective choice for industrial safety applications.

The Acrylic Coated Fiberglass Welding Blanket is engineered to provide dependable protection against welding sparks, spatter, and radiant heat during hot work operations. Constructed from woven fiberglass fabric and treated with a high-quality acrylic coating, this welding blanket delivers a strong balance of thermal resistance, durability, and flexibility for industrial environments.

The acrylic surface treatment enhances the fabric’s resistance to abrasion and mechanical wear while helping to contain sparks and molten metal droplets. This makes the blanket especially suitable for routine welding tasks where reliable protection is required without the added cost of heavy-duty high-temperature coatings.

Designed for ease of use, the Acrylic Coated Fiberglass Welding Blanket can be easily positioned over machinery, work surfaces, or surrounding areas to reduce fire risks and improve workplace safety.

This welding blanket is produced using a tightly woven fiberglass base fabric that offers natural non-combustibility and thermal stability. The acrylic coating is applied evenly to improve surface integrity and handling performance.

Fiberglass core resists flame and high temperatures

Acrylic coating minimizes fiber release

Enhanced resistance to sparks and spatter

Maintains flexibility during repeated use

The result is a protective blanket that performs consistently in demanding industrial conditions.

The Acrylic Coated Fiberglass Welding Blanket is suitable for applications involving intermittent heat exposure and frequent welding activity.

Reliable spark containment during welding and grinding

Good resistance to radiant heat

Stable performance in fabrication environments

Reduced surface damage compared to uncoated fiberglass

This performance profile makes it ideal for general-purpose welding protection.

Thanks to its versatile design, this welding blanket is widely used across multiple industries and job-site conditions.

Welding and cutting operations

Grinding and metal fabrication

Maintenance and repair work

Fire prevention during hot work

Equipment and surface protection

Metal fabrication plants

Construction and infrastructure projects

Automotive and machinery workshops

Shipbuilding and maintenance facilities

Different welding tasks require different protection levels. Acrylic coated fiberglass offers a practical solution for many standard applications.

| Material Type | Key Benefit | Best Use Case |

|---|---|---|

| Acrylic Coated Fiberglass | Balanced cost and performance | General welding protection |

| Silicone Coated Fiberglass | Higher heat resistance | High-temperature welding |

| Plain Fiberglass | Low cost | Light-duty protection |

| Vermiculite Coated Fiberglass | Extreme heat tolerance | Heavy industrial use |

For workshops seeking dependable protection without excessive material cost, acrylic coated fiberglass is often the preferred option.

Standard configurations are available, with customization options to meet specific project requirements.

| Parameter | Range |

|---|---|

| Thickness | 0.4 mm – 1.5 mm |

| Fabric Weight | 430 – 1200 g/m² |

| Coating Type | Acrylic |

| Colors | Gray, Black, Custom |

| Finishing | Plain, Reinforced Edges |

| Accessories | Eyelets / Grommets (Optional) |

We support OEM and private-label production for Acrylic Coated Fiberglass Welding Blanket solutions.

Custom dimensions and shapes

Edge reinforcement for extended durability

Metal grommets for hanging and fixing

Logo printing and private labeling

Roll form or finished blanket supply

Our production flexibility allows us to support both small-batch orders and large-scale industrial requirements.

To ensure optimal performance and service life:

Position the blanket securely to fully cover exposed areas

Avoid continuous direct flame contact

Allow cooling before handling after use

Store in a dry environment away from chemicals

Routine inspection is recommended to maintain safety standards.

Q1: What makes acrylic coated fiberglass suitable for welding blankets?

The acrylic coating improves durability, spark resistance, and handling while maintaining the fiberglass fabric’s natural heat resistance.

Q2: Can this welding blanket be reused?

Yes, it is designed for repeated industrial use when properly maintained.

Q3: Is it suitable for high-temperature cutting operations?

It is best suited for moderate to high intermittent heat. For extreme temperatures, silicone or vermiculite coatings may be recommended.

Q4: Are custom sizes available?

Yes, custom dimensions and OEM options are available upon request.

Q5: Does the blanket produce fibers during use?

The acrylic coating helps reduce fiber shedding compared to uncoated fiberglass fabrics.

The Acrylic Coated Fiberglass Welding Blanket offers a practical, durable, and economical solution for welding and hot work protection. With its reinforced surface, flexible handling, and reliable spark resistance, it is well suited for industrial workshops and fabrication environments seeking consistent safety performance.

| Fabric you can choose from BSTFLEX | Types of welding |

| Uncoated fiberglass welding blanket | Light, middle, heavy welding sparks |

| Heat treated fiberglass welding blanket | Light, middle, heavy welding sparks |

| PVC coated fiberglass welding blanket | Light welding sparks |

| Silicone coated fiberglass welding blanket | Light, middle, heavy welding sparks |

| Acrylic coated fiberglass welding blanket | Middle welding sparks |

| Silica fiber welding blanket | Heavy, Extreme heavy welding sparks |

| Silicone coated silica welding blanket | Heavy, Extreme heavy welding sparks |

| Vermiculite coated fiberglass welding blanket | Heavy, Extreme heavy welding sparks |

| Triple layer fiberglass welding blanket | Extreme heavy welding sparks |

| Carbon fiber welding blanket | Extreme heavy welding sparks |

| Size: 4'X6', 6' X 6', 6' X 8', 8' X 8', 10' X 10', 1m width X 50m roll length, or customized | |

Other Welding blankets & Welding blanket rolls products: