Silica Fabric Welding Blanket | BSTFLEX

Professional High-Temperature Welding Protection Manufacturer

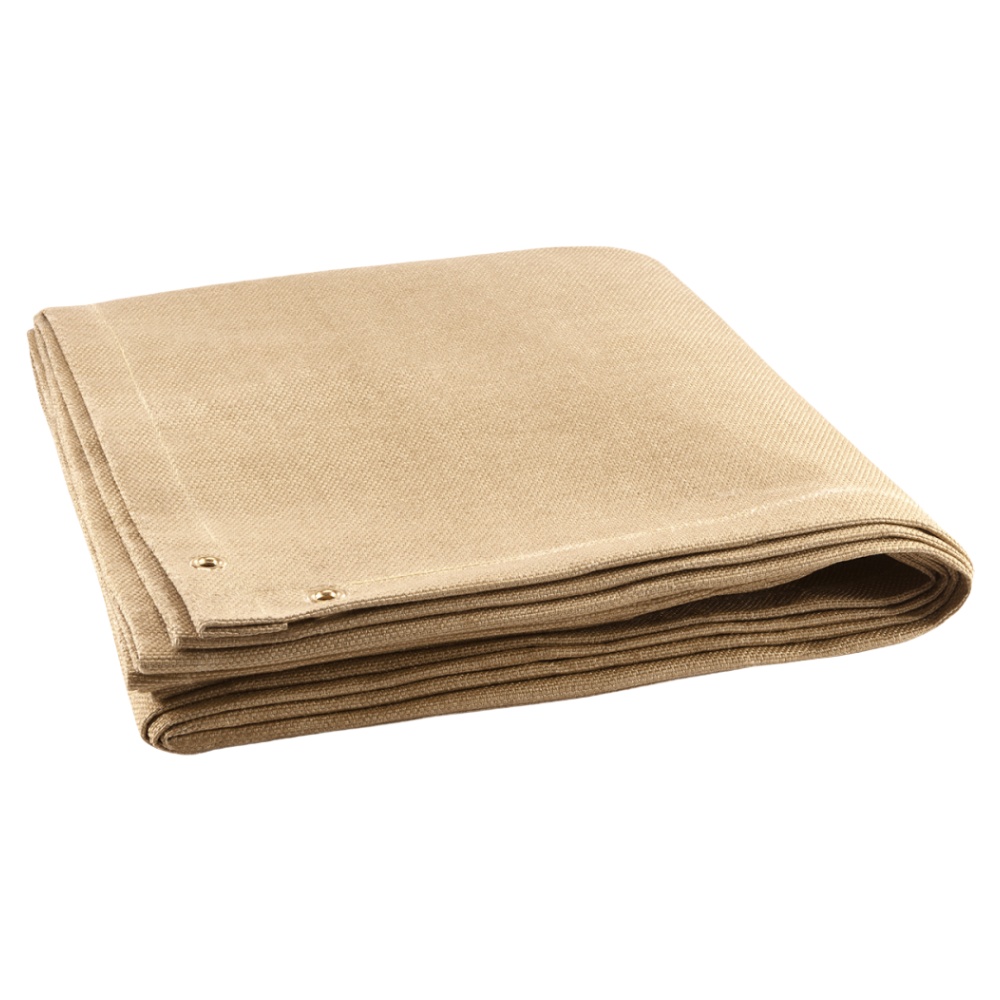

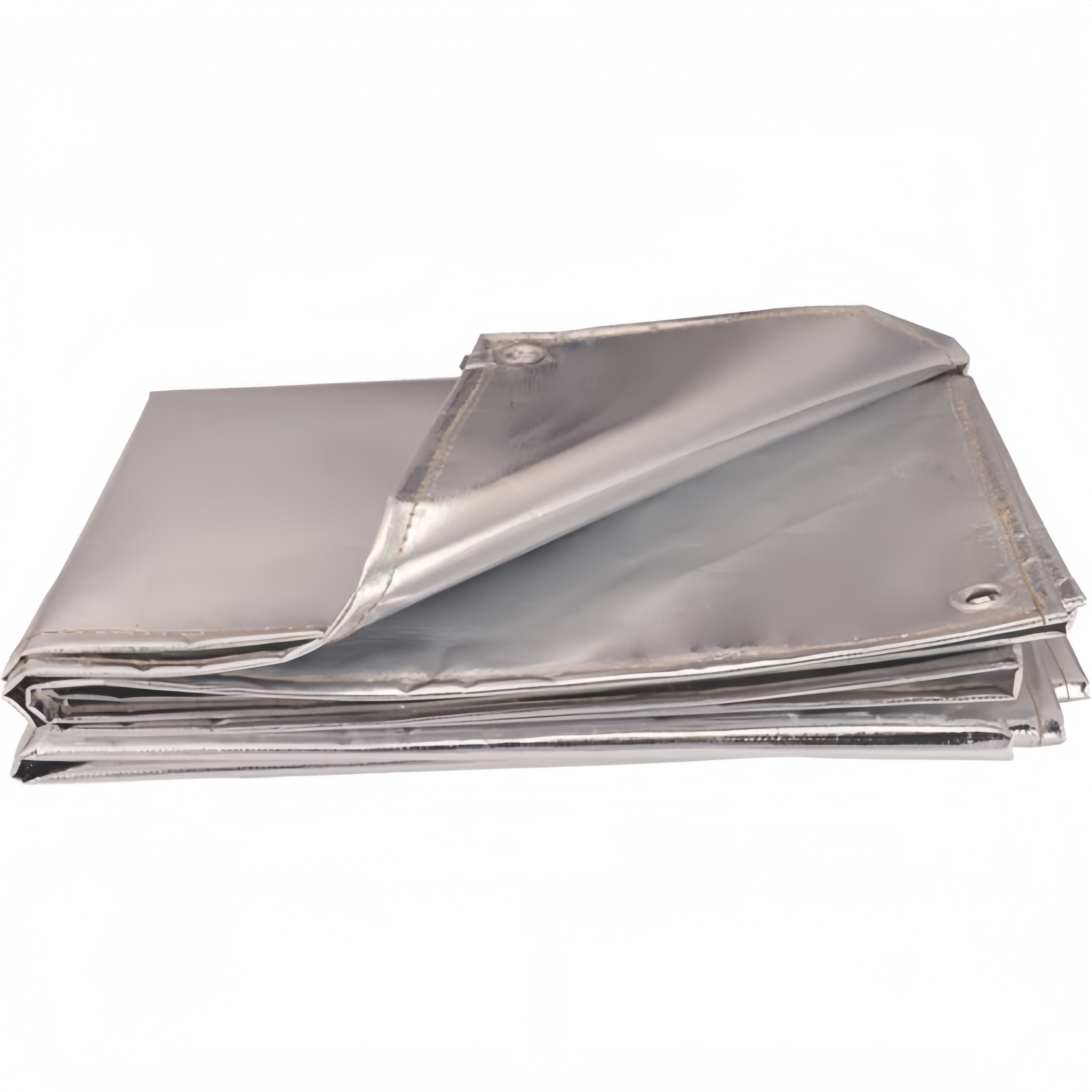

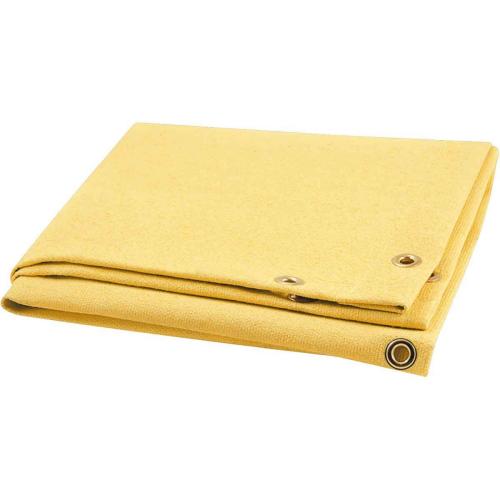

BSTFLEX Silica Fabric Welding Blanket is engineered for demanding welding, cutting, and high-heat industrial environments. Manufactured using high-purity silica fabric with advanced weaving technology, it provides outstanding thermal resistance, flame protection, and long-term durability.

As a professional manufacturer of high-temperature protection solutions, BSTFLEX supplies silica fabric welding blankets trusted by customers worldwide in metal fabrication, shipbuilding, oil & gas, power generation, and heavy industry.

What Is BSTFLEX Silica Fabric Welding Blanket?

BSTFLEX silica fabric welding blanket is produced from premium-grade silica fibers containing over 96% SiO₂. This specialized material delivers superior resistance to extreme heat compared to conventional fiberglass welding blankets.

Designed for continuous exposure to high temperatures, BSTFLEX silica fabric welding blankets effectively protect personnel, equipment, and surrounding areas from sparks, molten metal splash, and radiant heat during welding operations.

Key Specifications of Silica Fabric Welding Blanket

| Item |

Specification |

| Material |

High-purity silica fabric |

| Silica Content |

≥ 96% |

| Continuous Working Temperature |

Up to 1000°C (1832°F) |

| Short-Term Heat Resistance |

Up to 1200°C (2192°F) |

| Standard Thickness |

0.7mm / 1.0mm / 1.5mm |

| Surface Options |

Plain / Silicone Coated / Vermiculite Coated |

| Reinforcement |

Heat-resistant stitched edges |

| Supply Form |

Cut pieces or rolls |

Custom specifications are available upon request.

Why Choose BSTFLEX Silica Fabric Welding Blanket

-

Excellent flame and heat resistance for extreme welding conditions

-

Superior protection against molten metal splash and sparks

-

Low smoke emission and minimal fiber irritation

-

High mechanical strength and long service life

-

Flexible, reusable, and easy to install

-

Stable quality from batch to batch

BSTFLEX welding blankets are designed to perform reliably even in continuous, high-intensity industrial applications.

Typical Applications

BSTFLEX silica fabric welding blanket is widely used for:

-

Welding and cutting protection

-

Metal fabrication workshops

-

Shipbuilding and offshore platforms

-

Oil & gas processing facilities

-

Power plants and refineries

-

Automotive and heavy equipment manufacturing

-

Industrial fire protection and thermal shielding

Each application benefits from reliable, consistent heat protection engineered for industrial safety standards.

Silica Fabric Welding Blanket vs Fiberglass Welding Blanket

| Performance |

Silica Fabric |

Fiberglass |

| Continuous Temperature |

Up to 1000°C |

Up to 550°C |

| Heat Stability |

Excellent |

Moderate |

| Smoke Generation |

Very Low |

Higher |

| Durability |

High |

Medium |

| Recommended for Heavy Welding |

✔ Yes |

✖ Limited |

For high-temperature or long-duration welding operations, BSTFLEX strongly recommends silica fabric welding blankets over standard fiberglass alternatives.

BSTFLEX Custom Manufacturing Capabilities

As a direct manufacturer, BSTFLEX offers comprehensive customization services:

-

Custom sizes, shapes, and thicknesses

-

Optional silicone or vermiculite coatings

-

Eyelets, hooks, grommets, or reinforced edges

-

OEM branding and private labeling

-

Bulk production with stable lead times

Our engineering team works closely with customers to provide optimal thermal protection solutions for specific applications.

Quality Control & Certifications

BSTFLEX products are manufactured under strict quality control systems to ensure consistent performance and reliability. Our silica fabric welding blankets can be supplied with:

Technical datasheets and samples are available to support your evaluation and approval process.

Frequently Asked Questions (FAQ)

What temperature can BSTFLEX silica fabric welding blanket withstand?

BSTFLEX silica fabric welding blankets can withstand continuous temperatures up to 1000°C and short-term exposure up to 1200°C.

Is the silica fabric welding blanket reusable?

Yes. Under proper use, the blanket is reusable and maintains its protective performance over multiple welding cycles.

Can BSTFLEX provide custom sizes and OEM service?

Yes. We specialize in custom manufacturing, including size, thickness, coatings, and OEM branding.

Is it suitable for indoor welding operations?

Yes. The low smoke and low odor characteristics make it suitable for indoor and enclosed environments.

What is the difference between silica fabric and ceramic fiber welding blankets?

Silica fabric offers better flexibility and durability, while ceramic fiber provides higher insulation but is more fragile and less suitable for repeated handling.

Do you provide samples before bulk orders?

Yes. BSTFLEX can provide samples for quality evaluation before mass production.

Why Global Customers Choose BSTFLEX

-

Direct factory supply with competitive pricing

-

Stable production capacity and fast delivery

-

Professional technical support team

-

Extensive experience in high-temperature protection

-

Trusted supplier for international industrial customers

BSTFLEX is committed to providing reliable and cost-effective thermal protection solutions.

Request a Quote – Silica Fabric Welding Blanket

Looking for a trusted manufacturer of Silica Fabric Welding Blanket?

Contact BSTFLEX today for:

IPv6 network supported

IPv6 network supported